- [HOME]

- [COMPANY PROFILE]

- [PRODUCTS]

- [MANUFACTURERS]

- [REQUEST QUOTE]

- [CONTACT US]

|

|

The ventilation

system in chemical

laboratories occupies a special place. Its tasks are of primary

importance and

a high level of responsibility. Functions, performed by the system,

allow to

exclude undesirable situations and consequences important for human

health and

safety and security of goods and equipment. Depending on the

operations performed, laboratories

use a variety of chemical elements, perform technological operations

accompanied by the release of volatile components, smoke, gases, etc. The air in such

accommodations has a

high degree of responsibility, it will not only depend on the result of

work or

to keep the well-being, life or health. Thus, it is possible to combine

the

tasks performed by the ventilation system for laboratories: -good air

quality; -maintaining the

laboratory climate

(temperature, humidity) at a proper level; -elimination of

the spread of harmful

substances, the formation of hazardous concentrations or emissions; -prevention of

dangerous situations from

a fire point of view.

The organization

of the ventilation

system of chemical laboratories provides a fairly sophisticated

process, which

is based on the specificity of smelling and introducing. The need for

fresh air

will depend on the equipment used, technology and methods of operation.

The

design and installation of the system must be carried out with the

utmost care

and responsibility, excluding errors or miscalculations. |

|

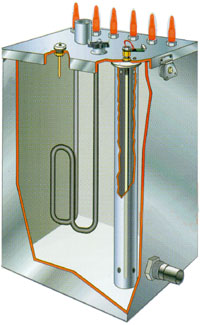

Multi-Steam:

For the most

efficient

steam absorption, N.E.P. developed 3 different steam dispersion methods

using the MULTI-STEAM, SAM or REGULAR distributors.

Multi-Steam:

For the most

efficient

steam absorption, N.E.P. developed 3 different steam dispersion methods

using the MULTI-STEAM, SAM or REGULAR distributors.

S.D.U.

(Space

Distribution Unit):

S.D.U.

(Space

Distribution Unit):