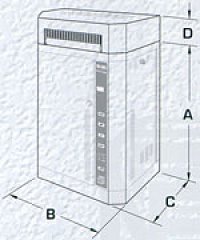

Dimensions

| Model | A | B | C | D+A | SDU |

| SK302 | 597mm 23-1/2" |

470mm 18-1/2" |

292mm 11-1/2" |

737mm 29" |

SDU-1 |

| SK304 | 597mm 23-1/2" |

470mm 18-1/2" |

292mm 11-1/2" |

737mm 29" |

SDU-1 |

| SK306 | 597mm 23-1/2" |

470mm 18-1/2" |

292mm 11-1/2" |

737mm 29" |

SDU-1 |

| SK309 | 597mm 23-1/2" |

470mm 18-1/2" |

292mm 11-1/2" |

737mm 29" |

SDU-1 |

| SK311 | 597mm 23-1/2" |

470mm 18-1/2" |

292mm 11-1/2" |

737mm 29" |

SDU-1 |

| SK314 | 724mm 28-1/2" |

533mm 21-1/2" |

318mm 12-1/2" |

890mm 35" |

SDU-2 |

| SK320 | 724mm 28-1/2" |

533mm 21-1/2" |

318mm 12-1/2" |

1048mm 41-1/4" |

SDU-3 |

| SK330 | 724mm 28-1/2" |

533mm 21-1/2" |

318mm 12-1/2" |

1048mm 41-1/4" |

SDU-3 |

| SK340 | 794mm 31-1/4" |

813mm 32" |

318mm 12-1/2" |

- | - |

| SK360 | 794mm 31-1/4" |

813mm 32" |

318mm 12-1/2" |

- | - |

SK300 SDU (SPACE DISTRIBUTION UNIT)

available on models SK302 to SK330